Now that we are approaching the middle of autumn, the weather has started to cool down dramatically, and since the temperature will see further reductions as we close in on the winter season, farmers should start considering what actions they will be taking to keep their chickens warm, cosy, and protected. A crucial method for keeping chickens safe is by building a chicken coop, as these structures offer protection from predators as well as shelter from the unforgiving autumn and winter weather.

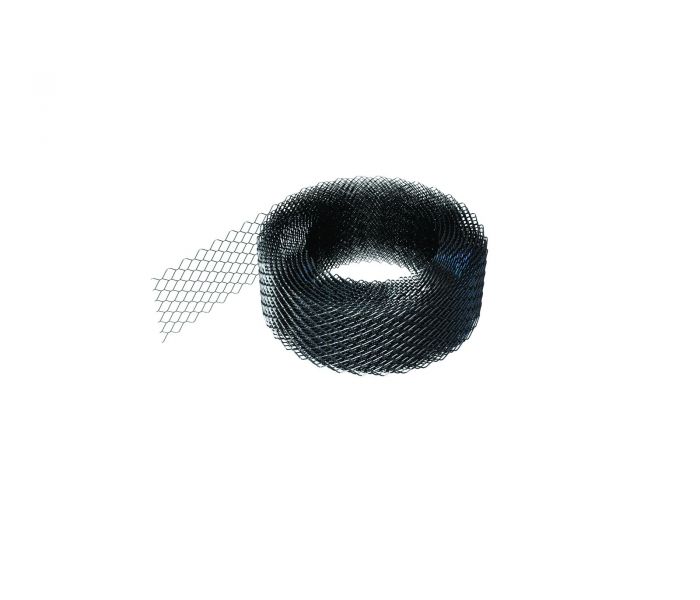

A key component of a chicken coop is chicken wire mesh, as it provides the bulk of a coop’s fencing due to its ability to withstand harsh weather conditions. As a supplier of chicken wire, we want to ensure that you can properly use it to create a safe environment for your chickens this autumn. This is why we have created a helpful guide on how to build a sturdy chicken coop with the use of chicken wire from BS Fixings.

As a supplier of chicken wire, we want to ensure that you can properly use it to create a safe environment for your chickens this autumn. This is why we have created a helpful guide on how to build a sturdy chicken coop with the use of chicken wire from BS Fixings.

What is Chicken Wire Mesh?

Chicken wire mesh (also known as chicken wire or poultry netting) is a type of wire fencing with hexagonal holes. Typically made from stainless or galvanised steel, this type of fencing is lightweight, flexible, and rust-resistant. This makes it great for use in outdoor structures, such as chicken coops.

Why is Chicken Wire Mesh Important for Chicken Coops?

Chicken wire mesh serves several important functions in a chicken coop:

- Security: chicken wire keeps predators, such as foxes, out, ensuring that your chickens remain safe.

- Durability: stainless and galvanised steel have weather-resistant qualities, which will prove very efficient during the autumn and winter months when rain and wind become more frequent.

- Ventilation: whilst coops can protect your birds from the cold, chicken wire also allows them to remain ventilated, allowing chickens to thrive in a healthy, air-rich environment.

How to Build a Chicken Coop

Before getting started, make sure you have all the tools and materials ready. Here’s a list of what you’ll need:

- Chicken wire mesh

- Wooden posts/beams

- Staple gun

- Wire cutters

- Hinges

- Roofing material

- Screws and Nails

- Hammer

Once you have all the essential tools, you can then begin to assemble your chicken coop by following these steps:

Step 1: Plan Your Coop’s Size and Layout

Before building, decide how large you want your coop to be. Make sure there’s enough space for each chicken and that the layout suits your land.

Step 2: Build the Framework

Construct a solid frame using wooden beams or posts. This forms the skeleton of your coop. Ensure this frame is strong enough to hold up against wind and rain.

Step 3: Install the Walls and Roof

Attach wooden planks for the walls and roofing material on top. Ensure the roof is angled to allow water to run off easily.

Step 4: Add Chicken Wire Mesh

Unroll your chicken wire mesh and cut it to size with wire cutters. Use a staple gun to secure it tightly to the frame. Make sure there are no gaps or loose ends, as these could let predators in.

Step 5: Build the Door

Install a door to give you easy access to the coop. Attach hinges and ensure the door fits snugly with no gaps where animals could sneak through.

Once you have followed these steps, you should end up with a sturdy chicken coop that offers protection from both the cold weather and any potential predators.

Reinforcing an Existing Chicken Coop with Wire Mesh

Even if you already have a chicken coop, it could still benefit from some extra protection. Here is a step-by-step guide on how to use chicken wire mesh to reinforce your coops:

Step 1: Inspect the Existing Coop

Look for any weak spots or damage within the coop. Pay special attention to areas that might let in wind, rain, or predators.

Step 2: Add Extra Layers of Chicken Wire Mesh

For added strength, consider using multiple layers of chicken wire mesh, especially on the roof and around windows. This provides additional protection from both weather and animals.

Step 3: Seal Any Gaps

Use chicken wire mesh to cover gaps in the coop, particularly along the base where predators might try to dig their way in.

How to Maintain Chicken Wire

As chicken wire provides the bulk of a chicken coop’s walls, it is important to know how to maintain it. Here are some top tips for prolonging the life of your chicken wire mesh:

- Check for rust or wear: even though chicken wire mesh is rust-resistant, it’s still worth checking for any signs of wear.

- Inspect for holes: make sure there are no holes or tears in the mesh that predators could exploit.

- Reinforce if necessary: if any areas seem weak, don’t hesitate to add more chicken wire mesh or other materials for reinforcement.

Building or reinforcing a coop with chicken wire mesh is one of the best ways to keep chickens safe and sound. Not only does it provide security against predators, but it also offers ventilation and protection from harsh elements. With the help of this guide and materials from BS Fixings, you can ensure that your coop is up to the challenges that autumn will bring.

Purchase Your Chicken Wire Mesh from BS Fixings

Here at BS Fixings, we offer a range of durable chicken wire mesh products that you can use to construct or reinforce your chicken coop. Here is an overview of what we sell:

Stainless Steel Chicken Wire Mesh:

The strong and durable nature of stainless steel makes it an ideal choice for chicken coop fencing, as it can withstand harsh weather conditions and resist tampering or damage. Its hexagonal pattern also allows for proper ventilation and airflow.

Galvanised Steel Chicken Wire Mesh:

The hot-dipped galvanising process involves immersing the steel wire in molten zinc, which forms a strong, protective coating that prevents rust and corrosion. This coating also makes the wire netting mesh more durable and resistant to damage from weather and environmental conditions.

Heavy Duty Galvanised Wire Mesh:

Also made from galvanised steel, our heavy-duty chicken wire mesh is ideal for use in outdoor settings, as it can withstand harsh weather conditions and exposure to moisture.

We don’t just offer products that help keep your chicken coops secure, however. We also stock many more fixings, fasteners, and building materials that you can use to help fortify your projects and help them withstand the harsher weather conditions. Click here to browse our full range today. If you have any questions, then feel free to email info@bsfixings.co.uk or call us on 03330 117818.

Now that we are approaching the middle of autumn, the weather has started to cool down dramatically, and since the temperature will see further reductions as we close in on the winter season, farmers should start considering what actions they will be taking to keep their chickens warm, cosy, and protected. A crucial method for […]

UK high streets were once the lively centres of towns and cities. But in recent years, they have been experiencing a steady decline due to factors like the rise of online shopping and changes in the economy. With these changes, traditional brick-and-mortar stores found it increasingly difficult to complete, leading to many closing their doors, leaving vacant storefronts behind, as well as new challenges for local communities.

However, amidst these struggles, there are new opportunities for transformation. Empty spaces are now being repurposed into mixed-use developments, blending residential, leisure, and commercial elements to bring new leases of life into these once-vibrant areas.

The team at BS Fixings takes pride in supplying building materials to help kickstart new builds and renovations, so we pay close attention to the developments within the UK construction world, and, in turn, like to keep you informed of our findings. This is what we have recently discovered about how UK high streets are being revived by government and council plans.

What Caused the Decline in Brick-and-Mortar Retail?

There are several factors responsible for the steady decline in UK high street shopping, with some of the most significant ones involving the rise of online shopping, economic factors, as well as the impact of the Coronavirus pandemic.

The Impact of Online Shopping

One of the most profound changes to shopping in recent decades is the rise of online retail. Large wholesale platforms, like Amazon, as well as online stores from various popular brands, have changed the way people shop, promoting more digitally driven consumers.

This can be attributed to the convenience that online shopping provides, with products being able to be viewed on a phone and get delivered right to a buyer’s doorstep, negating the need to venture to a physical location at all.

The Impact of Economic Changes

Economic factors also played a significant role. The financial crash of 2008, as well as the cost-of-living crisis in recent years, have both impacted the level of people’s disposable incomes. With less money to spend, consumers would become more cautious, leading to a reduction in shopping trips. On the other side, rising rental costs also meant that businesses were finding it more and more difficult to sustain their presence on the street, even driving some to close permanently.

The Impact of the COVID-19 Pandemic

Whilst the rise of online shopping was impactful enough on its own, it was further accelerated by the coronavirus pandemic. Due to multiple government-enforced lockdowns, non-essential retail stores were forced to close for extended periods, drastically reducing footfall and revenue. With physical shops shut, consumers relied on online shopping for their needs, further shifting their purchasing habits away from high streets. This led to a significant decline, with 17,500 chain store outlets disappearing in 2020 alone.

The Rise of Empty Spaces and Deserted Shopping Centres

With the closure of numerous shops, high streets across the UK have been left with large amounts of unused space. Entire shopping centres that once thrived are now shells of their former selves, often falling into disrepair. The appearance of these derelict places makes the surrounding areas less attractive to potential visitors, causing even more issues for local communities.

How is this Issue Being Tackled?

Rather than being left to deteriorate and drag down the images of communities, developers have seen potential in repurposing these spaces by building mixed-use developments to bring back engagement and meet new needs.

Residential Areas

One of the main examples of mixed-use developments is the inclusion of residential areas. With housing shortages across the UK, redeveloping empty retail spaces into residential units addresses the current housing problem and brings people back to the high street. As residents will now be living close to brick-and-mortar retailers, there is a greater chance of them engaging with the surrounding stores.

Leisure Facilities

Leisure facilities, such as cinemas, gyms, cafes, and restaurants, are also being incorporated into these mixed-use developments. These spaces provide recreational aspects that aim to attract people back to the high street, encouraging them to spend time and money in their local area.

Examples of UK High Street Developments

There are already several examples of high streets that have been transformed or are currently going under transformation into thriving mixed-use spaces:

Transformed Spaces:

- Wokingham Town Centre: The town centre of Wokingham has been revitalised over the past five years in their council’s bid to adapt the town to changing circumstances. Changes include a new public square with shops, bars, restaurants, and homes at Peach Place. There is also a Premier Inn hotel that surrounds a beautiful, landscaped park.

- Barnsley Town Centre: A £200 million Glass Works project played a pivotal role in transforming the market of Barnsley Town Centre, creating modern spaces for retail and leisure businesses, as well as a public square that is the centre of many events.

Ongoing Projects:

- The Galleries: This £135 million project aims to provide the town centre of Wigan with a vibrant new retail, leisure, commercial, and residential destination. The new area will include a cinema, bowling alley, music venue, and much more. The old Galleries building has already been demolished, with redevelopment underway.

- Crewe Town Centre: This regeneration programme for the town centre of Crewe sets out a number of priorities, including the delivery of the Royal Arcade scheme as a mixed-use attraction.

Final Thoughts

Whilst the decline of brick-and-mortar retail on the UK high streets has brought challenges, it has also promoted forward-thinking, leading to many strategies using mixed-use developments. These action plans have helped breathe new life into towns and cities, helping to create vibrant, multi-purpose spaces that meet the needs of today’s communities, and with more redevelopments being planned and carried out, the future for high streets is looking bright.

Bring Life into Your Builds with BS Fixings

If you are looking to revive and refurbish your old builds and projects, then look no further than BS Fixings. We offer a range of high-quality building materials, fixings, and decorating products in our bid to help your builds look as good as new. Browse our website to discover the full extent of what we offer, or contact us with any questions you need answering.

UK high streets were once the lively centres of towns and cities. But in recent years, they have been experiencing a steady decline due to factors like the rise of online shopping and changes in the economy. With these changes, traditional brick-and-mortar stores found it increasingly difficult to complete, leading to many closing their doors, […]

When working with masonry brick mesh is an extremely important tool in creating rigid and durable brickwork. BS Fixing’s brick mesh, available in different widths and in both galvanised and stainless steel, is a crucial component that will ensure the stability and lifespan of your masonry projects. If you’re unfamiliar with brick mesh or need a refresher, don’t worry, as we have written this blog to help you out!

What is Brick Mesh?

Brick mesh (also known as brick reinforcement mesh or masonry mesh) is used to reinforce brick structures by adding strength and stability. It consists of strips of thin metal mesh arranged in a lattice pattern, which are embedded in the mortar between bricks to provide additional support and help maintain the structure’s integrity over time.

Improving the Sturdiness of Brickwork

By embedding the mesh within the mortar, it helps improve the strength of the brickwork. The mesh can withstand tensile stresses, vibrations, and thermal changes that would cause movement within the structure, keeping the brickwork from cracking or breaking. Brick mesh can also help distribute loads more evenly across the structure, which can help them withstand vibration and sudden loading.

Improving the Appearance of Brickwork

Beyond its structural benefits, brick mesh is also important for achieving a neat and professional look. Cracks can ruin the appearance of brickwork, so using brick mesh ensures that the mortar joints remain consistent and even, which is essential for keeping masonry walls looking uniform.

Types of Brick Mesh

- Stainless Steel Brick Mesh- stainless steel mesh offers excellent corrosion resistance, making it great for use in harsh environments and outdoor constructions.

- Galvanised Brick Mesh - galvanised steel mesh is more cost effective than stainless steel, which means it is slightly less effective when it comes to anti-corrosion properties. However, it is well suited to interior brickwork where corrosion is less of a risk.

Installing Your Brick Mesh

Correctly installing your brick mesh is extremely important. Here are a few things to keep in mind when installing.

Step One: Picking the Right Size

It’s important to determine what size of brick mesh you need and ensure that it’s trimmed to fit the dimensions of your project. Using the wrong size mesh can compromise the integrity of the brickwork. If your mesh size is too large, it may not properly embed in the mortar or distribute loads effectively enough. If your mesh size is too small, mortar joints may become overcrowded, making it difficult to properly lay and align the bricks.

Step Two: Correctly Attaching to Brickwork

Brick mesh should be laid in strips between every 3 brick courses, keeping a 25 mm gap from the work’s faces. When joining two lengths, overlap them by at least 75 mm. Failing to secure the mesh properly can lead to poor load distribution, increased risk of movement, and reduced structural integrity. These factors can lead to improperly reinforced brickwork that can move, absorb water, or even collapse under stress.

Brick Mesh is one of the the key factors in ensuring the endurance of your brickwork. It prevents cracks, ensures even lines, and adds strength to the structure of brick projects. Whether you’re a seasoned professional or a DIY enthusiast, incorporating brick mesh into your next project is a great way to achieve a high-quality finish.

Is your next project going to involve masonry? If so, take a look at our brick mesh at BS Fixings. We offer both stainless and galvanised steel, helping builders carry out various brickwork projects with confidence. To find out about what else we offer, browse our full product range today, or get in touch by calling us on 03330 117818 if you have any questions.

When working with masonry brick mesh is an extremely important tool in creating rigid and durable brickwork. BS Fixing’s brick mesh, available in different widths and in both galvanised and stainless steel, is a crucial component that will ensure the stability and lifespan of your masonry projects. If you’re unfamiliar with brick mesh or need […]

We know that outdoor light displays are a must when preparing to celebrate the Christmas season, with their vibrant colours and designs helping create a festive atmosphere that really brings about the spirit of Christmas. But hanging them up properly is a necessity for ensuring that they are displayed safely and in a way that they can reach their aesthetic potential.

This is where sign fixing clamps come into play, acting as secure fasteners to prevent light exhibits from damage, unsightly looks, and other potential hazards. In this blog, we’ll explain exactly how they work, as well as how to use them so that you can take part in creating a winter wonderland.

Why Proper Installation Matters

Christmas light displays that are improperly installed can have several negative consequences. Firstly, they are quite unsightly, often comprising of tangled messes that drive attention away from the festive atmosphere. Beyond aesthetics, however, unsecure light displays can also pose numerous safety hazards, as lights can fall or get damaged, potentially leading to electrical issues, injuries, and fires.

What are Sign Fixing Clamps?

Sign Fixing Clamps are sturdy, versatile fasteners that are commonly used to attach signs and lights to poles, walls, and other surfaces. Their primary function is to provide a secure grip that can be tightened or loosened easily, ensuring that lights and signs can be precisely positioned. As well as the security they provide, their construction, using materials like stainless steel, helps them withstand harsh weather conditions, making them great for outdoor use.

How Sign Fixing Clamps Work

Sign fixing clamps consist of two main parts: the band and the tightening mechanism. The band is the flexible part of the clamp that wraps around the surface you want to attach the lights/signs to. Once the band is in place, the tightening screw is used to secure the clamp, providing a firm grip. This mechanism can also be unscrewed and reused, giving them optimal reusability.

How to Use Sign Fixing Clamps

Here is a step-by-step guide to using sign fixing clamps, which you can follow to setup a great festival display:

- Plan your display: before starting, decide where you want to place your lights and measure the area.

- Prepare the clamps: choose the appropriate clamp size and material for your surface.

- Position the lights: arrange the intended display items along the surface, making sure that they are evenly spaced to increase their visual appeal.

- Attach the clamps: wrap the clamp around the surface and place it over the wire of the lights.

- Tighten the clamps: secure the clamp by tightening the screw or bolt. Make sure the grip is firm but not too tight to avoid damaging the lights.

- Check for security: once all the clamps are in place, give the lights a gentle tug to ensure that everything is securely fastened.

Safety Considerations

While you can find great enjoyment in decorating for the festive season, it is crucial to make sure that safety is always at the forefront of your mind, and this involves considering other factors beyond the security of your displays. You should also check the suitability of your lights, making sure that they are designed for outdoor use. It is also wise to inspect them for signs of damage, such as frayed wires or broken bulbs, before and after installation. You should power up your Christmas lights with outdoor-rated extension cords and ensure that they are not overloaded to avoid the risk of a fire starting. Finally, it is best practice to install them in dry weather to avoid the possibility of electric shocks.

Tips for an Eye-Catching Christmas Light Display

Now that you know how to use sign fixing clamps, here are some top tips for designing a beautiful Christmas light display that will truly pay tribute to this wonderful occasion.

- Use a Variety of Lights: Mixing different types of lights together, such as string lights, icicle lights, and snowflake lights, can help give your display an extra element of depth, making it less one-dimensional. This depth is further exemplified when multiple vibrant colours are also used.

- Highlight Architectural Features: you can use your lights to accentuate the unique aspects of nearby buildings, such as windows, doorways, and rooflines.

- Add Timers: Consider using timers to automatically turn your lights on and off. This saves energy and ensures that your display is glowing bright at the right times.

Purchase Your Sign Fixing Equipment from BS Fixings

At BS Fixings, we offer high-quality sign fixing clamps and tools that you can use to help set up your winter light exhibition or in other signage projects. Here is what we have on offer:

TAMTORQUE® Sign Fixing Clamps

These clamps are excellent at keeping your signs secure since they can only be fastened and unfastened using the unique Tamtorque Tools, making them anti-theft and more secure than traditional clamps.

TAMTORQUE® - T-Bar Driver Tool

The T-Bar Driver Tool comes with a unique seven-sided socket bit that allows them to be used for fastening and unfastening our sign fixing clamps. They are quick and easy to use and are able to be reused for multiple projects.

TAMTORQUE® - Driver Power Bits

If you wish to have a quicker installation and removal process, then our Driver Power Bits are the way to go. These power bits, which carry the same unique properties as our T-Bar Driver Tools, can also be used to secure your signage projects.

It may feel like Christmas is a long time off, but your festive displays are a lot less likely to look good and remain in-place if they are set up in a last-minute hurry. Buy your sign fixing clamps today at BS Fixings and ensure that you are fully prepared. To find out more about what we offer, browse our full product range here, and if you have any questions, then feel free to contact us.

We know that outdoor light displays are a must when preparing to celebrate the Christmas season, with their vibrant colours and designs helping create a festive atmosphere that really brings about the spirit of Christmas. But hanging them up properly is a necessity for ensuring that they are displayed safely and in a way that […]

We are delighted to announce that on Sunday, 13th October, a team of 12 dedicated members from BS Fixings will be participating in the Manchester Half, an event that aims to represent the wonderful people of Manchester and celebrate their achievements. This event will be particularly special and exciting for our team, as for many, it will be their first half-marathon.

The decision to participate in this half marathon wasn’t just about personal achievement. The team at BS Fixings saw it as an opportunity to give back to the community by supporting two incredible charities. The first of these is St Catherine's Hospice, a local charity in Preston that is renowned for its compassionate palliative and end-of-life care, serving individuals with life-limiting illnesses such as cancer, motor neurone disease, and heart failure. What sets this charity apart is its commitment to providing support not only within their own environment but also in the homes of those in need, ensuring that patients are looked after in the setting that suits them best. Supporting St Catherine’s means contributing to the comfort and dignity of those facing some of life’s most challenging moments.

The second charity that we have chosen to support is Macmillan Cancer Support. What we admire about Macmillan is that the charity doesn’t just address the physical aspects of this disease; they also provide crucial financial and emotional support, helping patients and their families navigate the wider issues that come with a cancer diagnosis. By making sure that people can access the resources and support they need, Macmillan makes it possible for those living with cancer to maintain a sense of normalcy and control over their lives during an incredibly tough time.

In preparation for this special occasion, we are reaching out to our community to help us fuel the charities that make a big difference in people’s lives. Whether through donations or by simply spreading the word, your support can have a significant impact on lives across the UK. We’ve set up dedicated fundraising pages for both St Catherine’s Hospice and Macmillan Cancer Support, and every contribution, no matter the size, brings us one step closer to our fundraising goals. Your generosity will directly support these charities in continuing their essential work.

Click Here to Donate!

Get Involved!

If you’re feeling inspired by our fundraising efforts, then why not participate in a charity event yourself? You’ll be helping support the hard work of charities across the nation as well as raising awareness for certain diseases and illnesses. There will be plenty of fundraising events taking place across the UK, so look for one near you and give it a go!

We are delighted to announce that on Sunday, 13th October, a team of 12 dedicated members from BS Fixings will be participating in the Manchester Half, an event that aims to represent the wonderful people of Manchester and celebrate their achievements. This event will be particularly special and exciting for our team, as for many, […]

As a supplier of durable, long-lasting building materials and fixings, we are always looking to introduce new products to diversify our collection and offer even better assistance for our customers. One of our latest additions is our steel bed joint reinforcement ladders (also known as masonry reinforcement ladders), which are great for enhancing the strength and durability of brick/block walls.

With many new products, there will usually be several questions that follow, usually asking about what it is and how beneficial it can be. In this blog, we will provide informative answers to frequently asked questions about bed joint reinforcement; so that, by the end, you will have a better understanding of its function and benefits, as well as why and when to use it.

What is a Bed Joint in Construction?

In construction, a bed joint refers to the horizontal layer of mortar on which masonry, such as bricks, are laid, acting as the surface that supports the weight of the next layer. Bed joints are crucial in distributing loads evenly across a structure and to help bond the individual units together, helping create a strong and stable masonry wall.

What is Bed Joint Reinforcement?

Bed joint reinforcement refers to steel wire or mesh, usually being horizontally embedded within the mortar joints in between the layers of masonry bricks or blocks. Typically, bed joint reinforcements consist of two parallel wires that are connected by cross wires, forming a ladder shape. The extra endurance provided helps distribute loads more evenly and can control cracking that is caused by shrinkage, temperature changes, or external forces such as wind.

When is Bed Joint Reinforcement Required?

Bed joint reinforcement is required in masonry construction under specific circumstances to enhance structural integrity and reinforce potential stress points. Here are some of the instances that indicate when bed joint reinforcement is needed:

1) Increase Structural Support

These reinforcements are typically required to provide structural support, especially in areas where walls may experience higher amounts of lateral forces such as winds. This includes multi-story buildings, retaining walls, or masonry structures built in coastal areas.

2) Crack Control

In masonry, cracks can occur because of temperature changes or the natural shrinking of materials over time. Supporting the bed joints can help distribute stress more evenly, reducing the risk of cracks forming.

3) Openings and Weak Points

Openings such as doors and windows especially need to be reinforced, as the areas of masonry surrounding them will naturally be more exposed to movement and stress. The use of bed joint reinforcement ladders can help maintain the strength of these areas, resisting against cracks or displacement.

4) Different Settlements

When buildings are constructed on different types of soil or foundations, there can be uneven settling, potentially causing stress on the walls and increasing the chances of cracking, fractures, or other forms of damage. Bed joints can be used to counteract damage caused by differential movement.

How Thick Should a Bed Joint be?

The thickness of these joints can vary, as factors such as the type of construction and materials used must be taken into consideration, but for brick masonry, bed joints should be around 6-9mm thick. The joint should be thick enough to support the structure without protruding from the mortar.

Where Can They be Used?

Bed reinforcements can be used for a wide range of masonry applications, such as in residential housing, commercial buildings, and apartment complexes.

Where to Find Strong Bed Joint Reinforcement?

You can find strong and durable bed joint replacement ladders right here on our website. We have recently added these to our lineup of handy building materials in our bid to help you get going on your next construction activity.

About our Stainless Steel Bed Joint Reinforcement Ladder

High-Quality Construction

Our bed joint ladders are made from high-quality stainless steel, making them excellent for withstanding corrosion and remaining strong for a long time.

Versatile

These ladders come in a standard length of 2.7 meters and are available in a number of wire diameters, making them suitable for various brick/block widths.

Easy to Install

Our bed joint ladders are also relatively easy to install, making them a convenient solution for reinforcing your brickwork walls.

Fast Delivery

We offer next-day delivery for our most popular sizes, and for our less-popular ones, we offer quick turnaround times so that no matter what size of brick reinforcement you need, you can get the job done fast.

BS Fixings aims to provide a range of dependable building materials to help you build stable structures that will stand the test of time. From wall ties and compression sleeves to our new bed joint reinforcement ladders, our array of building materials is ever-evolving to fit your construction needs. Be sure to browse our full range of building materials today or call us on 03330 117818 if you have any questions.

As a supplier of durable, long-lasting building materials and fixings, we are always looking to introduce new products to diversify our collection and offer even better assistance for our customers. One of our latest additions is our steel bed joint reinforcement ladders (also known as masonry reinforcement ladders), which are great for enhancing the strength and […]

The Building Safety Act, originally passed by the UK government in 2022, proved to be a noteworthy step forward in enhancing the safety of buildings across England, as well as giving residents and homeowners more rights, powers, and protections. As a supplier of high-quality building materials, we also recognise the importance of building safety, which is why we are here to inform you about the latest amendments made to this legislation, and what they mean.

A Brief History of the Building Safety Act

This Building Safety Act came around after the Grenfell Tower fire in London, 2017. This tragic event, which claimed 72 lives, highlighted several critical issues around English building in terms of how they were constructed and managed. The disaster firstly uncovered serious flaws in current building regulations, such as the use of aluminium composite material cladding (ACM), which not only contributed to the rapid spread of the fire due to its flammability, but was also found to be used on as many as 486 other high-rise buildings across the UK. As well as this, it also came to light that existing safety regulations were not enforced sufficiently enough, allowing buildings like Grenfell Tower to function with hundreds of non-compliant fire doors, that did not form tight seals or close behind residents.

The Building Safety Bill was first introduced to the UK Parliament in July 2020 before gaining Royal Assent and becoming a formal law in April 2022. The Act promised to outline measures to deliver far-reaching protections for leaseholders from the costs of fixing historical defects, overhaul existing regulations, as well as create three new bodies to provide effective oversight of the new regime.

The Latest Amendments

There have been several amendments made to the Building Safety Act which were enacted through the Leasehold and Freehold Reform Act 2024. These measures, which recently came into force on the 24th July, make the following changes:

Cost of Litigation

Section 117 of the Leasehold Act states that residents in a ‘Right to Manage’/Resident Management company who run their own buildings can apply for a Remediation Contribution Order and split the costs among a group of leaseholders by permitting these to be passed on via the service charge.

This is a limited exemption to the leaseholder protections under the Building Safety Act, which otherwise protects qualifying leaseholders from freeholders passing on the costs of litigation.

Repeal of Section 125

Section 118 of the Leasehold and Freehold Reform Act 2024 resolves a conflict between Insolvency Law and Section 125 of the Building Safety Act, which would have allowed amounts recovered through the courts for remediation costs under the Building Safety Act to be distributed to creditors in the first instance. It is Insolvency Practitioner’s legal duty to prioritise paying off creditors under the Insolvency Act. The new Section 118 of the Leasehold Act repeals section 125 of the Building Safety Act and so prevents the latter legislation from being used to secure funds for creditors rather than being used for remediation.

This amendment means that leaseholders and owners cannot take advantage of the Leasehold Act and use it to apply for remediation funds to pay off creditors, maintaining the integrity and intended purpose of Remediation Contribution Orders.

Notification of Insolvency

The insolvency of an accountable person can have implications for the safe management of a building which is subject to the Building Safety Act. The new Section 125A of the Building Safety Act (as amended by Section 119 of the Leasehold Act) puts a duty on Insolvency Practitioners who are appointed to the insolvency of the owner or leaseholder of a residential building, which is at least 5 storeys high, to notify local authorities and fire and rescue services. In the case of higher risk buildings (buildings which are 7 storeys high), Insolvency Practitioners must also notify the Building Safety Regulator.

This amendment will ensure that regulators can engage with both the Insolvency Practitioner and/or residents to check the building is being safely managed during insolvency proceedings. This amendment takes steps to make sure that buildings remain safe even in the event of their owners/leaseholders landing themselves in debt.

These latest amendments to the Building Safety Act focus on ensuring that Remediation Contribution Orders are distributed fairly and lawfully, as well as making certain that buildings are kept safe even in the event of their owners amassing debt, overall increasing the effectiveness of the act and helping keep English houses safe.

At BS Fixings, we fully understand the importance of carrying out construction and DIY safely to minimise the risk of injury or structural failures and believe this is only achievable when you invest in quality products and equipment. In support of this, we only stock high-quality building materials and fixing tools that can help you build and secure your next project. Browse our collection to find the right products for your needs or email us at info@bsfixings.co.uk with any questions.

The Building Safety Act, originally passed by the UK government in 2022, proved to be a noteworthy step forward in enhancing the safety of buildings across England, as well as giving residents and homeowners more rights, powers, and protections. As a supplier of high-quality building materials, we also recognise the importance of building safety, which […]

Climate change is affecting the planet every day and is already changing how we live. From global warming and rising sea levels to extreme weather events, the environmental challenges we face today demand a more proactive approach to how buildings are designed. In this article, we look at some of the current issues caused by climate change and how modern building design is having to adapt.

Rising Temperatures

One of the most significant impacts of the changing climate is the rise in global temperatures. Higher temperatures can increase the stress on certain building materials, such as timber and concrete. Air conditioning systems are used more often, which in turn leads to higher energy consumption, which contributes to the problem even more.

Adapting to Rising Temperatures

Building designers are now using design elements that help buildings stay cool without having to rely heavily on an air conditioning system. An example of this is green roofs. The roof space is covered with vegetation providing good insulation, and the process of evaporation also helps cool the air surrounding the building.

Architects are now having to pay greater attention to the design of the ventilation and airflow within the building, with more traditional elements being used to provide increased shading, such as blinds, curtains, external shutters, and awnings, which aim to shield the buildings from direct natural sunlight, helping maintain a stable temperature.

The construction industry is looking to heat-resistant materials and reflective surfaces that are all aimed at reducing the impact on the environment.

Extreme Weather Events

There is an increasing occurrence of extreme weather events across the globe, such as hurricanes, wildfires, heavy rainfall, and flooding. Buildings must now be designed to endure these extremes by incorporating materials and techniques that offer greater resilience and safety.

Adapting to Extreme Weather Events

Buildings in areas that are at higher risk from wildfires are now being designed using materials that are fire-resistant, such as brick, stone, and concrete. The external designs are being changed to include fire-break areas with minimal vegetation and ensuring there are no trees within 10 feet of the building. They may also incorporate elements such as clay roof tiles and tempered glass, with fire-resistant cladding becoming another feature that is being incorporated into modern building design.

Traditional gable roofs that form an inverted V-shape are more prone to wind damage because of the large flat surface area being subjected to the force of the wind. In areas that are seeing an increased risk of hurricanes and extreme winds, these are being replaced with hipped roofs. Hipped roofs have four slopes, allowing the wind to pass over the surface of the roof with less resistance, meaning the roof is less likely to be damaged. Architects are having to be more aware of local wind patterns and aerodynamics.

Along with rising temperatures mentioned earlier, climate change can also bring about occurrences of extreme cold. This means that building designs also need to consider how they can be better insulated and minimise snow drifts. We have already mentioned that green roofs can be useful for insulation purposes, but in areas of high snowfall this solution can cause issues with snow collection causing drifts on roof tops, which can cause stress on the roof structure and safety concerns for falling snow. Designers are countering cold climates with steeper slopes on roofs and slippery surfaces that prevent snow from collecting. Buildings are now being designed with high-efficiency heat pumps that provide both heating and cooling to the interior.

Rising Sea Levels

For buildings in coastal areas, the rising sea level is a major concern. Buildings in these regions require special considerations when being designed, including elevated foundations and flood barriers, to help prevent and mitigate water damage.

Adapting to Rising Sea Levels:

Raising the foundations of a building above the expected flood level for the area will help to protect it from any floodwaters, and incorporating sump pumps can remove any water from crawl spaces and basements. Incorporating flood barriers, whether man-made or using natural landscaping, around or near buildings is an effective method for protecting them from floods. These barriers can redirect water to drainage areas, helping to contain or divert floodwaters away from the structures and reduce the risk of water accumulation around the buildings.

As we look to the future, it’s clear that adapting building design to change in the climate is no longer optional; it’s essential. By designing buildings with special considerations that can counteract the effects of climate change, these structures not only become increasingly resilient but also more environmentally responsible.

We hope you found this article informative, increasing your awareness of environmental issues that the construction and building industry faces and the adaptation strategies that are being used to deal with the future climate. Are you ready to get started on your next building project? Browse our full range of building materials, or contact us by calling 03330 117818.

Climate change is affecting the planet every day and is already changing how we live. From global warming and rising sea levels to extreme weather events, the environmental challenges we face today demand a more proactive approach to how buildings are designed. In this article, we look at some of the current issues caused by […]

The Construction industry is always seeing new innovations, whether those are high-performance materials, advanced tools, or modern techniques. Among these innovations are changes to fixings and fasteners, which have begun to see not just technical improvements, but also benefits that make construction safer, more efficient, and even more eco-friendly. Here’s a look at some new innovative fixings and fasteners, which are helping contribute to the continuous development of the construction industry.

New Innovations:

Eco-Friendly Fasteners

One of the latest all-round trends in construction today is sustainability, and this has extended to fasteners and fixings. Eco-friendly fasteners are made from materials that have a lower environmental impact. These include biodegradable polymers or recycled metals like steel. Check out our posts on Eco-friendly materials and Stainless Steel. Some fasteners are also designed to be more easily removed and recycled at the end of their lifecycle, helping reduce waste in construction projects.

Corrosion-Resistant Coatings

Corrosion is one of the biggest obstacles for metal fasteners, especially in environments exposed to moisture or chemicals. Traditional fasteners often require frequent replacement in such conditions, leading to higher costs and potential safety risks. However, the development of corrosion-resistant coatings has helped combat these issues. These coatings help shield the fasteners from rust and degradation.

A good example of this is galvanisation, which involves hot-dipping steel screws with a layer of zinc. Some advanced coatings that are applied via plating or spraying also offer additional benefits, such as resistance to ultraviolet light, which can further extend the lifespan of fasteners used in outdoor or exposed environments. Some of the latest innovations are green electroplating techniques that reduce the amount of toxic solvents used in the process, and Graphene plating. Graphene is a new material that is stronger than steel and has excellent electrical and heat conductivity properties.

High-Performance Screws

Screws are among the most used fasteners, and they have seen significant innovation in recent years. High-performance screws are designed to offer better grip, more effortless driving, and increased load capacity. This means they can hold materials together more securely, even under high stress or in challenging conditions.

One of the recent innovations includes self-drilling screws, which are equipped with a drill bit-like tip, allowing them to be driven directly into materials without the need for a pre-drilled pilot hole. This not only speeds up the construction process but also reduces the chances of splitting the material, ensuring a stronger hold.

We offer a range of self-drilling screws to buy online.

Adhesive Fasteners

Adhesive fasteners represent a significant departure from traditional mechanical fasteners. These use specially formulated adhesives to bond materials together. While adhesives have been used in construction for some time, the latest innovations have made them much more reliable and versatile.

Modern adhesive fasteners, like those from brands such as Unibond, are designed to offer strong bonding power while remaining flexible, allowing for some movement between the materials without compromising the bond. This flexibility is particularly useful in environments where materials may expand or contract due to temperature changes. Adhesive fasteners are also often used in situations where traditional fasteners might not be practical, such as bonding glass panels or attaching materials to surfaces that cannot be easily drilled.

Reusable Fasteners

As the construction industry becomes more focused on sustainability, reusable fasteners have gained popularity. These fasteners are designed to be easily removed and reused in other projects, reducing the need for new materials and lowering overall costs. These are particularly valuable in temporary structures or situations where components may need to be disassembled and reassembled.

BS Fixings: A Reliable Provider

When it comes to sourcing innovative fixings and fasteners, BS Fixings is here to lend you a helping hand. We proudly offer a wide range of products that cater to the needs and demands of both small DIY projects and large construction sites. Amongst our range, we offer corrosion resistant screws and nails, which will help protect your outdoor projects against the elements. Browse our range of products today or call us on 03330 117818 with any questions.

The Construction industry is always seeing new innovations, whether those are high-performance materials, advanced tools, or modern techniques. Among these innovations are changes to fixings and fasteners, which have begun to see not just technical improvements, but also benefits that make construction safer, more efficient, and even more eco-friendly. Here’s a look at some new […]